Figma

Flutter

Balsamiq

Jira

Jun - Aug 2024 (3 months)

For many manufacturing organizations, critical workflows are still tethered to desktop-based systems. Shop-floor workers must leave their stations to reconcile inventory, supervisors lose time on paper-based tracking, and managers are often stuck waiting to approve documents until they return to their desks. These inefficiencies cause bottlenecks, delay projects, and frustrate employees across all roles. While existing ERP and HR platforms provide powerful tools, they often lack mobile-first solutions designed for quick, context-driven tasks on the go.

There are countless apps for enterprise-level manufacturing execution systems (MES), document review

software, and HR services like time tracking, but there are very few that combine the functionality of two

of the above, much less all three. Proton aims to fill this niche as a companion app to my client's existing

hybrid software, while also serving as a competitor to several existing apps.

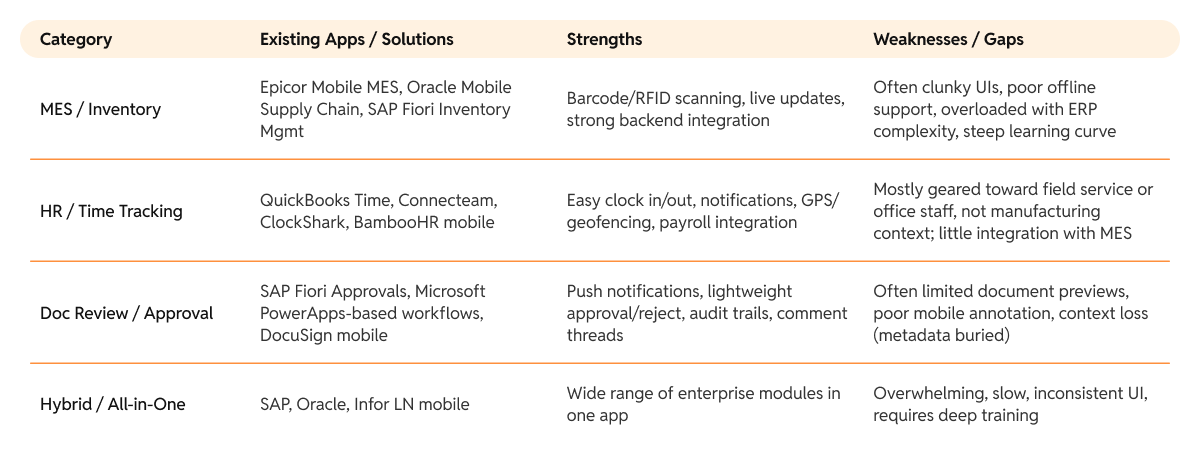

Based on my competitor research, I created a benchmarking matrix of existing adjacent apps to highlight what

they do well vs. where they struggle. This should help me create pain points to address as I design.

Key tasks like approvals, time entry, and inventory updates were locked to desktop systems, forcing delays and inefficiencies.

Project managers often returned to stacks of pending documents, slowing projects and frustrating cross-functional teams.

Operators struggled with confusing interfaces and inconsistent inventory data, making it difficult to quickly identify, locate, and reconcile parts during active builds.

From these findings, I developed two user personas to represent the multiple users of

the app.

First, this is María, a senior technician who spends most of her time on the manufacturing floor. She wants

to streamline her process and reduce errors while keeping track of inventory in real time.

Next is Daniel, an engineering manufacturing PM who is often on the go. He could perform his tasks

like document review and time entry on a mobile device if such a solution existed, and hopes that a

companion app for his company's MES could improve his efficiency.

María has spent over 10 years working in manufacturing. She started as a line worker, and after years of hard work, was promoted to senior technician, where she oversaw part picking and assembly prep. She's known for her speed and accuracy, and she trains junior staff on her workflows, including picking parts and updating inventory manually, reconciling inventory on paper, and setting up workstations on time. She is comfortable with technology, but prefers simple, reliable tools that don't interrupt workflow while helping to reduce human error.

Daniel is an engineering PM who oversees multiple production lines in several different countries. He spends part of his day on-site, part in the office, and part traveling between facilities, but he needs to stay responsive while mobile; approving documents, monitoring workflow, and checking in with teams are crucial parts of his job. He is comfortable with enterprise tools, but frustrated by the desktop-only bottlenecks of his current MES software.

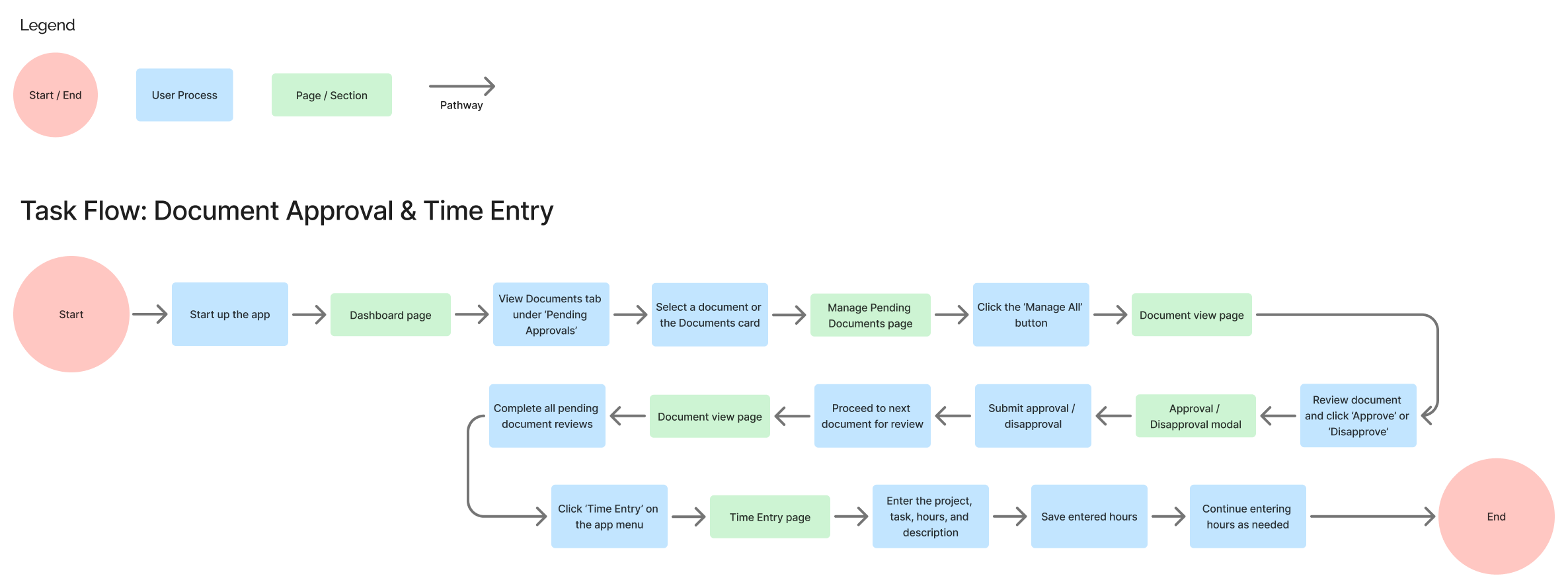

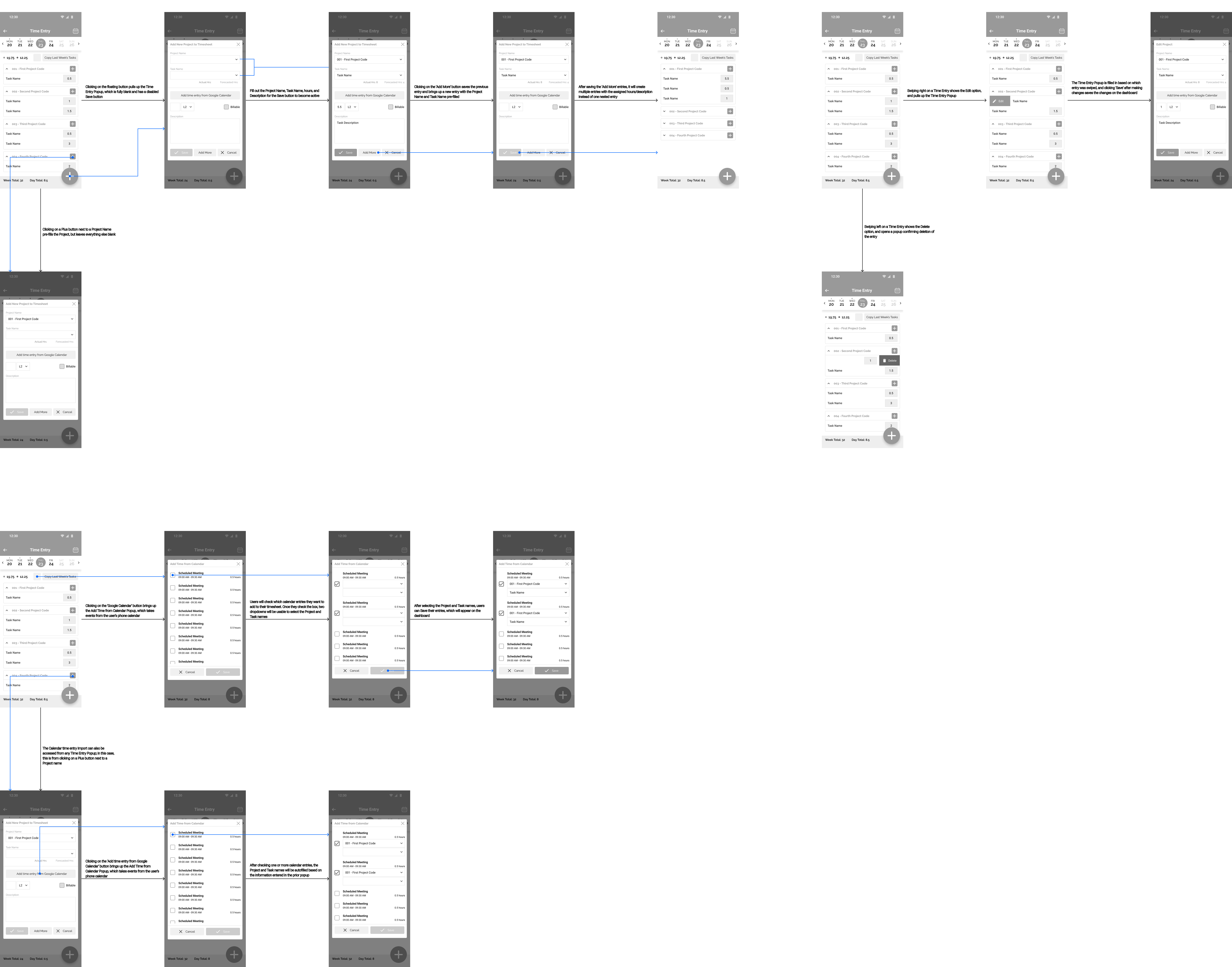

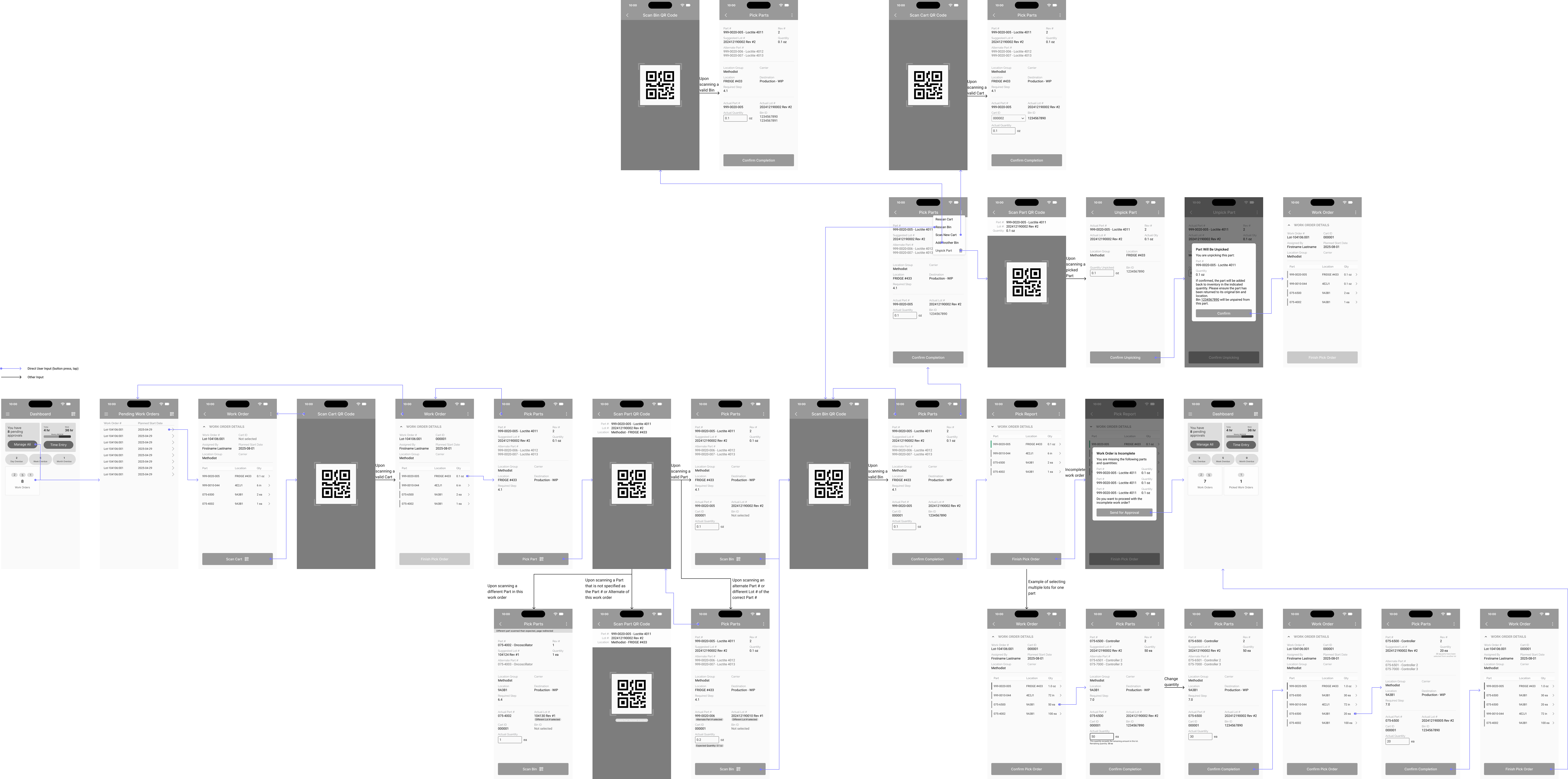

To define the scope of the app and ensure a smooth user experience, I thought through various user needs and

created task and user flows. These flows covered basic app tasks like reviewing documents, picking and

reconciling parts, and time entry. This helped clarify the essential steps, decision points, and potential

friction within each journey.

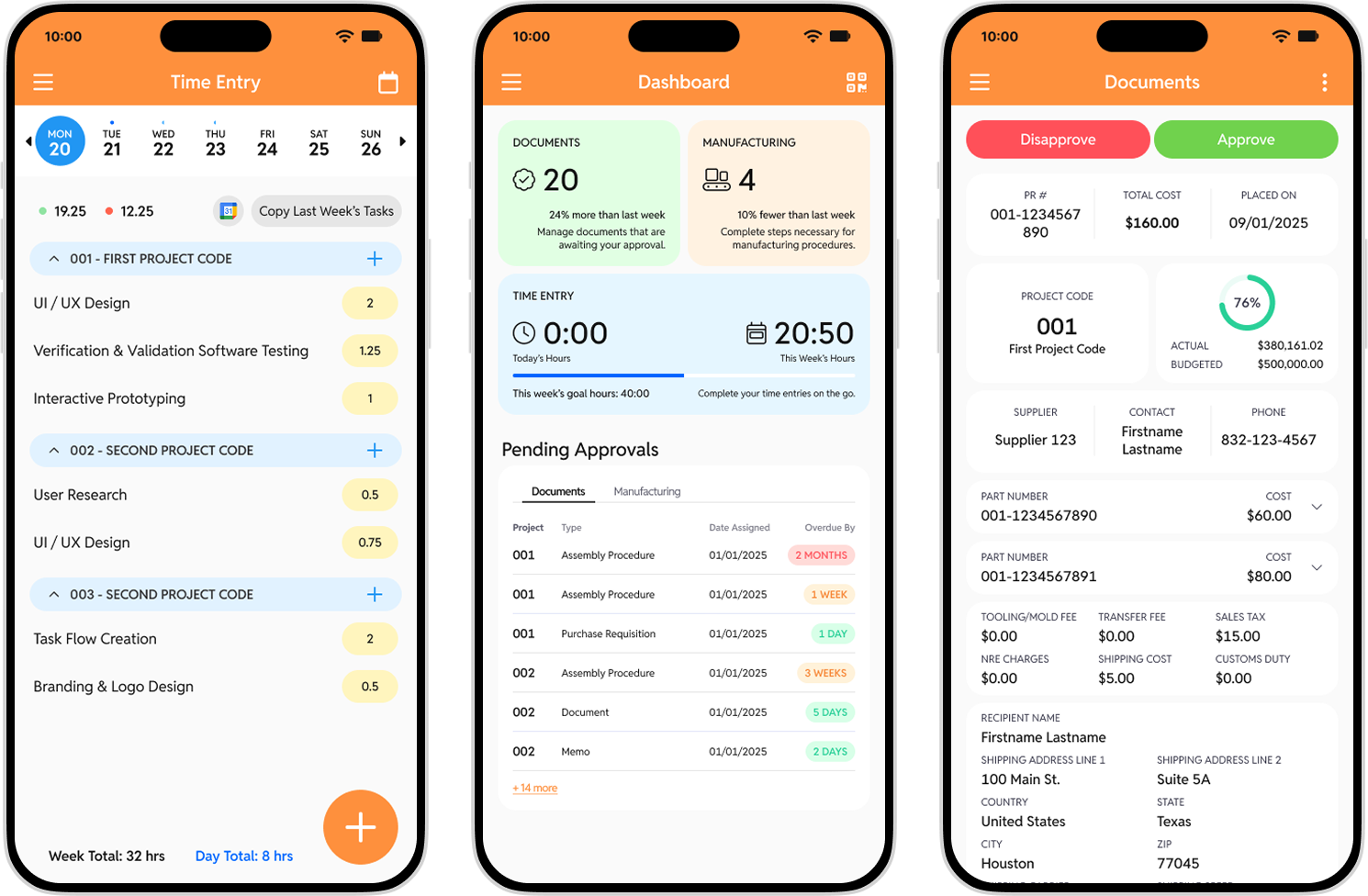

This is the task flow for approving a document, then entering work

hours into the app:

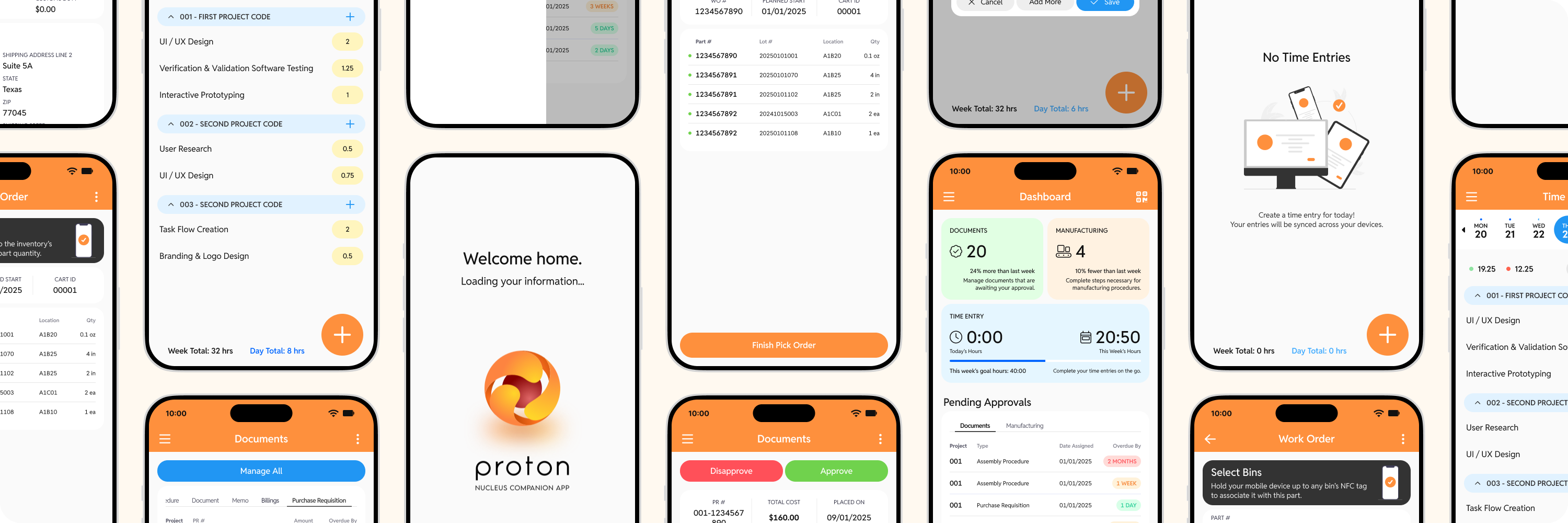

From these task and user flows, I began ideating on the designs of my main screens. The Dashboard would of

course be where users start their journeys. From there, based on their needs, users could navigate to the

Document Review, Manufacturing, or Time Entry modules from interactive cards on the dashboard, or a slide

out menu accessible from any page.

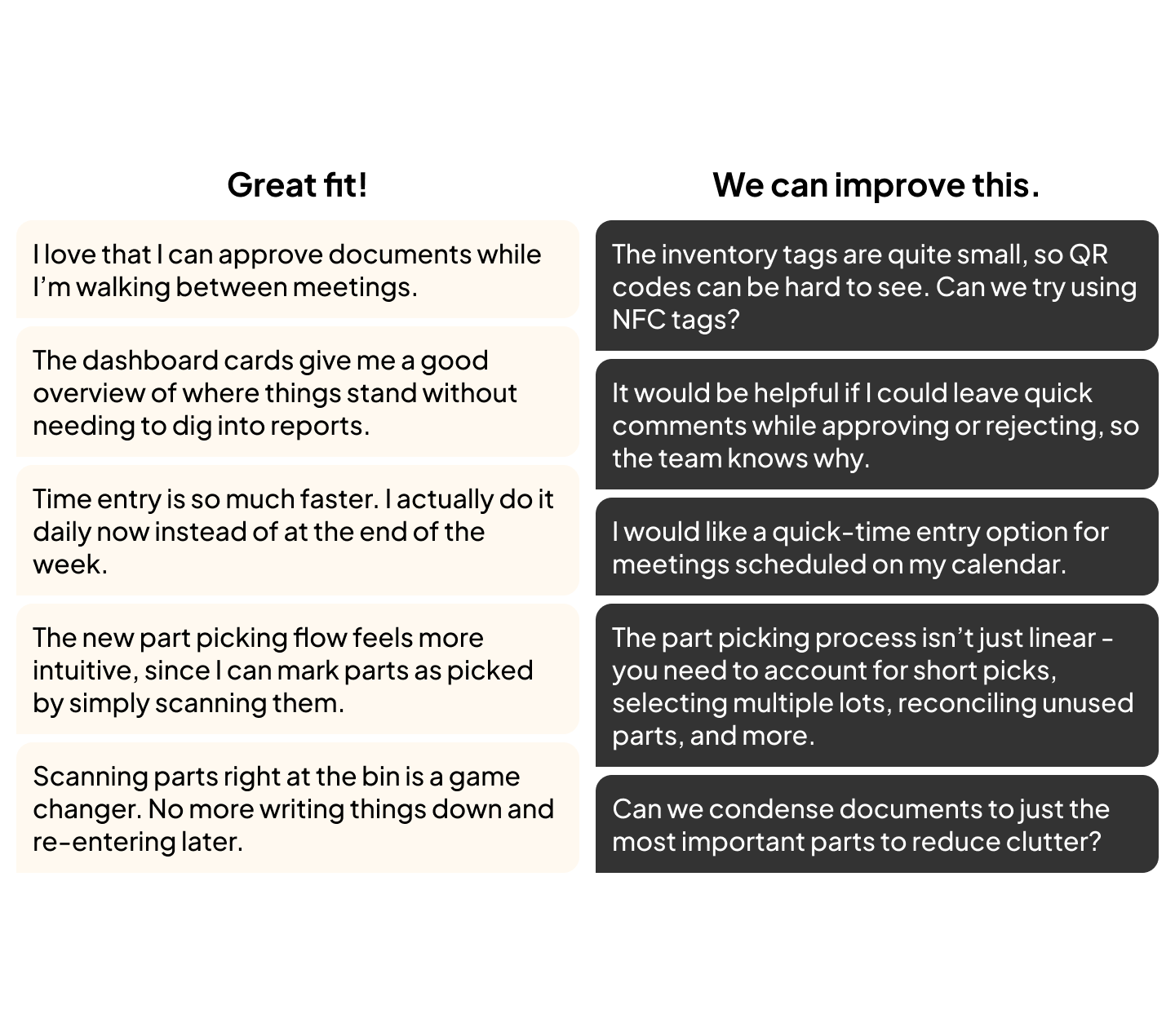

In the mid-fi screen flows below, I incorporated user feedback and attempted to make the journey streamlined

and easy to use.

Time Entry Flow

Manufacturing Flow

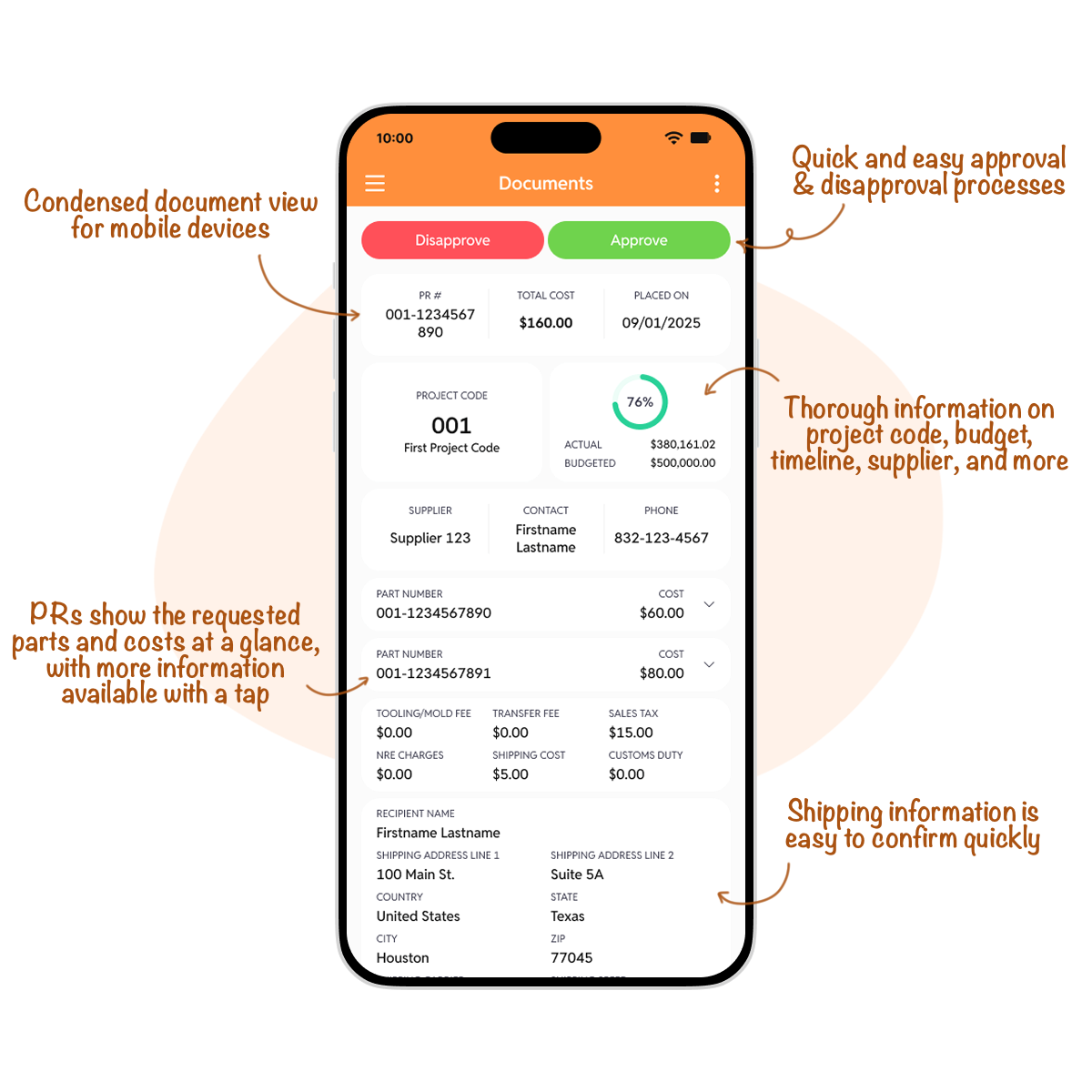

Reviewing and approving documents is now as simple as a few taps. The interface

highlights the most important details upfront, with clear action buttons for approve or reject.

Contextual previews keep information concise yet accessible, so project managers can stay decisive

without digging through files.

Review and approve critical documents from any device with a clear, simplified interface. A

streamlined approval flow ensures nothing gets stuck waiting for sign-off, keeping projects moving

forward.

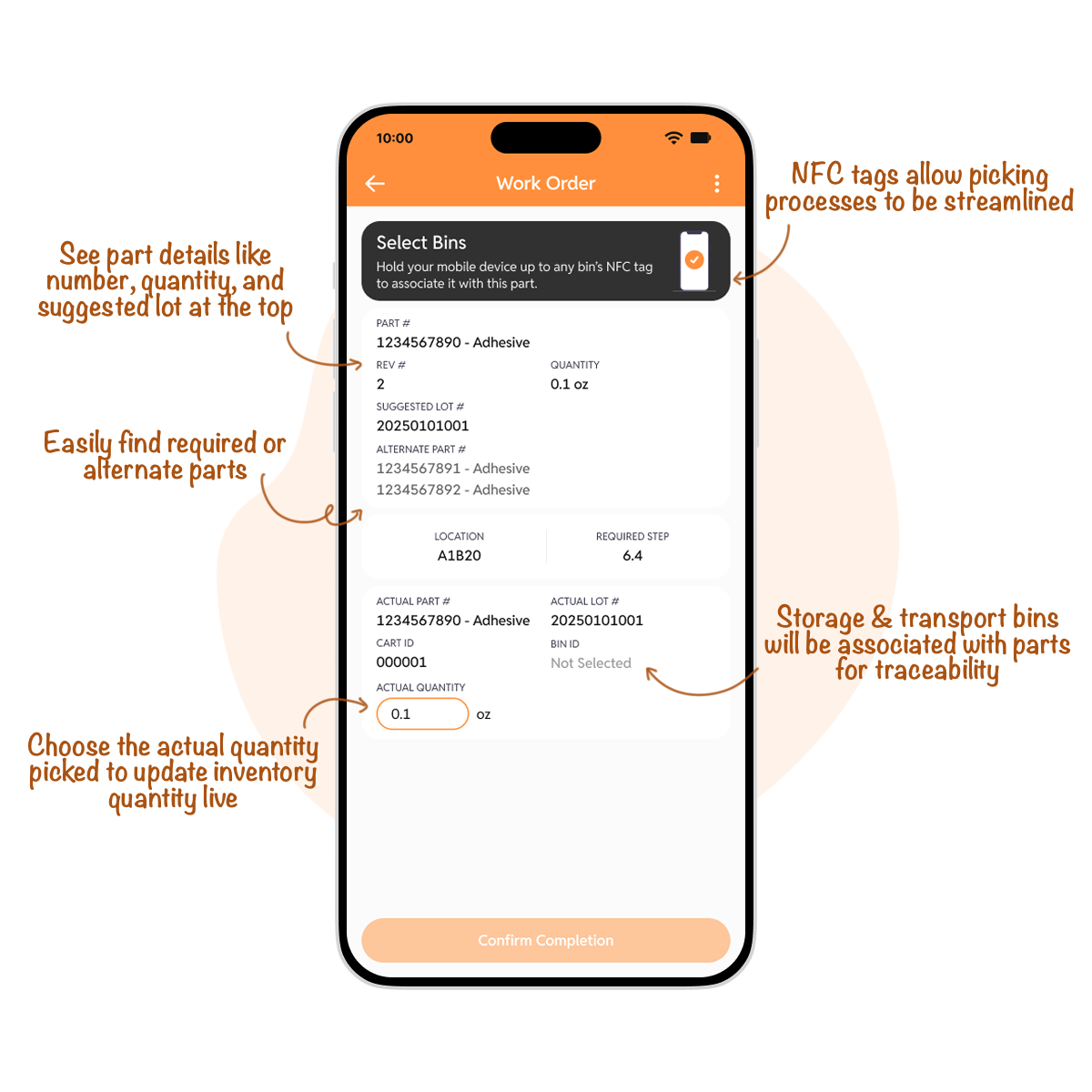

The MES flow brings live inventory management to the shop floor. Workers can tap NFC

tags directly at storage locations, verify counts, and reconcile discrepancies instantly. By

eliminating paper slips and re-entry steps, the app reduces errors and ensures the central system

always reflects reality.

The new part picking interface puts clarity first. Operators can view assigned parts by priority,

see real-time stock levels, and mark items as picked in just a few taps.

With a more guided workflow and intuitive layout, teams spend less time searching and more time

building.

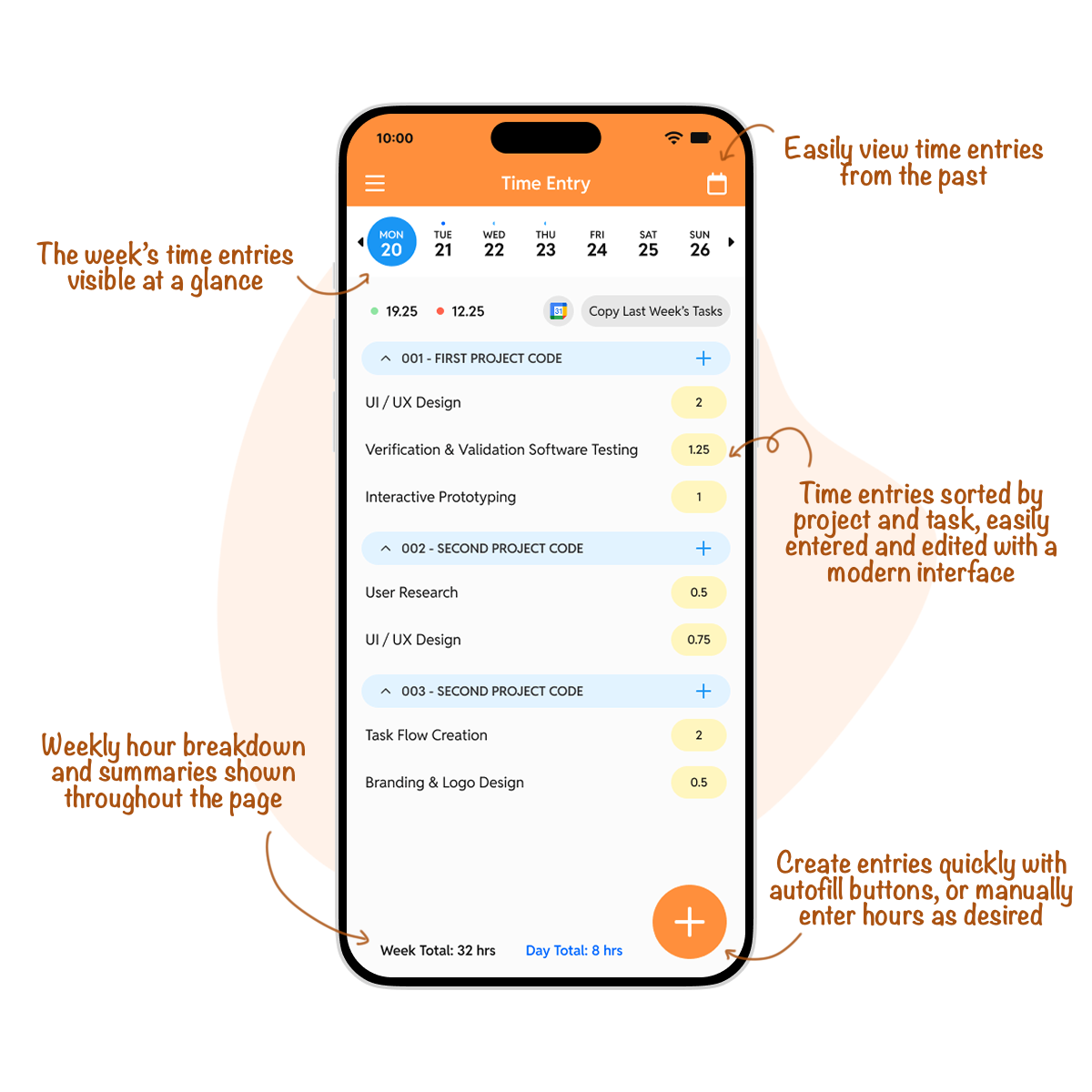

A lightweight time-entry interface gives employees control of their schedules on the

go. Quick clock-in/out, editable manual entries, and a weekly hours summary make it easy to stay on

top of payroll. Clear indicators flag missed or incomplete entries, helping employees and HR avoid

surprises.

Entering hours shouldn't be a chore. The redesigned time entry screen simplifies the process to just

a few inputs, while smart defaults and saved task categories speed up repeat submissions.

Users can log time daily, weekly, or retroactively with ease - and integrated validation ensures

records are accurate before submission.

It's everything users need to keep projects on track, without slowing them down.

While early feedback from internal stakeholders has been positive, future rounds of usability testing will focus on validating the efficiency and intuitiveness of each workflow. Key metrics to measure include:

These metrics will help us refine navigation patterns, optimize task flows, and identify opportunities for additional automation or predictive features.

There are several promising enhancements could further elevate the experience and extend the app's capabilities. AI-powered suggestions for common part replacements or approval workflows based on historical data could streamline the PM workflow and reduce project turnaround. Adding offline capabilities would enable critical actions like part picking and time logging without a network connection. Finally, cross-system integrations to create deeper connections with scheduling, procurement, and supplier systems could reduce data silos and improve planning.

This project reinforced the importance of prioritization in mobile design - the

companion app couldn't replicate the full enterprise suite, so success depended on identifying the

2 or 3 tasks with the greatest impact per role. Furthermore, I learned the value of balancing

simplicity with depth, helping me create interfaces that feel effortless for everyday

users while still supporting the complexity of industrial operations.

Additionally, I refined my skills in translating stakeholder requirements into actionable user

goals, aligning technical constraints with design decisions, and advocating for mobile-first design

in traditionally desktop-bound workflows. Most importantly, I gained a stronger appreciation for how

thoughtful design can directly impact operational efficiency, team collaboration, and business

outcomes.

Illustration Credit: unDraw

Stock Image Credit: Pexels